Driven by team spirit, hard work, dedication and the honesty of our employees and partners, we guarantee precision and closeness through:

Response time flexibility — Product diversification — Highly specialized production — Rigor, monitoring and customization — Cutting-edge production and quality control technology.

As a starting point to meet our clients quality standards, we inspected all fabrics.

In our internal laboratory we test the future to ensure perfection.

We start testing on the sample development stage and make sure that any potential hazards are anticipated. Rigorous tests, physicals and chemicals, are performed at every stage of the process, from the raw material to the final product including accessories.

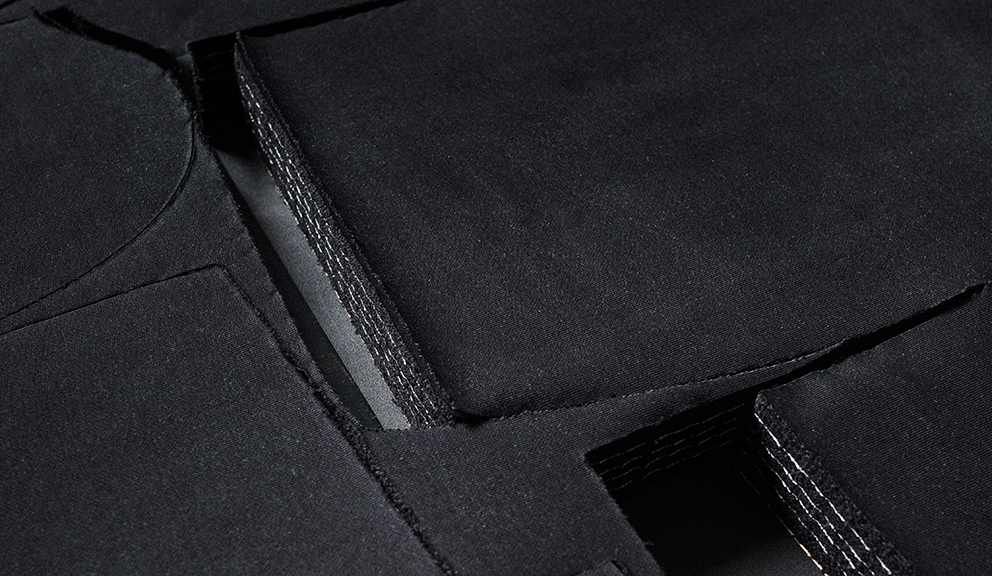

Cutting expertise for flawless garments.

In our in-house cutting department we cut all garments according to high-performance processes resulting from recent investments in high-tech pattern-cutting machines.

Confection is part of our DNA.

Our in house confection and finishing boasts a long history of knowledge and experience supported by high standards of quality.

Throughout each stage, quality control is essential to ensure that the final product meets the highest quality standards.

We optimize quality and time. Smart procedures ensure production and distribution efficiency. In our 10.000 m2 warehouse we stock hundreds of different fabrics and distribute garments with high precision to all world destinations of our clients.

Versatile and rigorous, our industrial model brings together the best of many modes of operation, including specialization and diversification and puts them to work in a high-performance network. In addition to our inhouse staff, a high qualified team controls our various partner factories to ensure standardization of procedures and compliance with customer requirements.